Manufacturers across industries rely on durable and reliable metal parts to meet demanding operational requirements. For automotive, aerospace, and industrial applications, advanced manufacturing technologies are reshaping how components are designed, produced, and maintained. This article explores key innovations driving the creation of high-performing metal parts and practical insights into adopting these technologies in your operations.

Contents

- 1 1. Precision Engineering with CNC Machining

- 2 2. Strength and Efficiency with Additive Manufacturing

- 3 3. Enhanced Properties Through Heat Treatment

- 4 4. Material Innovation with Metal Alloys

- 5 5. Quality Assurance with Non-Destructive Testing (NDT)

- 6 6. Automating Supply Chains with AI and IoT

- 7 7. Incorporating Green Manufacturing Practices

1. Precision Engineering with CNC Machining

CNC (Computer Numerical Control) machining offers unparalleled accuracy in producing precision metal parts. Using computer-guided tools, CNC technology can create complex geometries with tolerances as tight as ±0.005 inches. Industries like aerospace and medical devices value CNC machining for delivering consistent results across large production volumes.

By utilizing this advanced manufacturing method, downtime caused by faulty parts is minimized, leading to increased efficiency and reduced costs. For optimal results, many manufacturers pair CNC machining with 3D modeling software to test designs virtually before production.

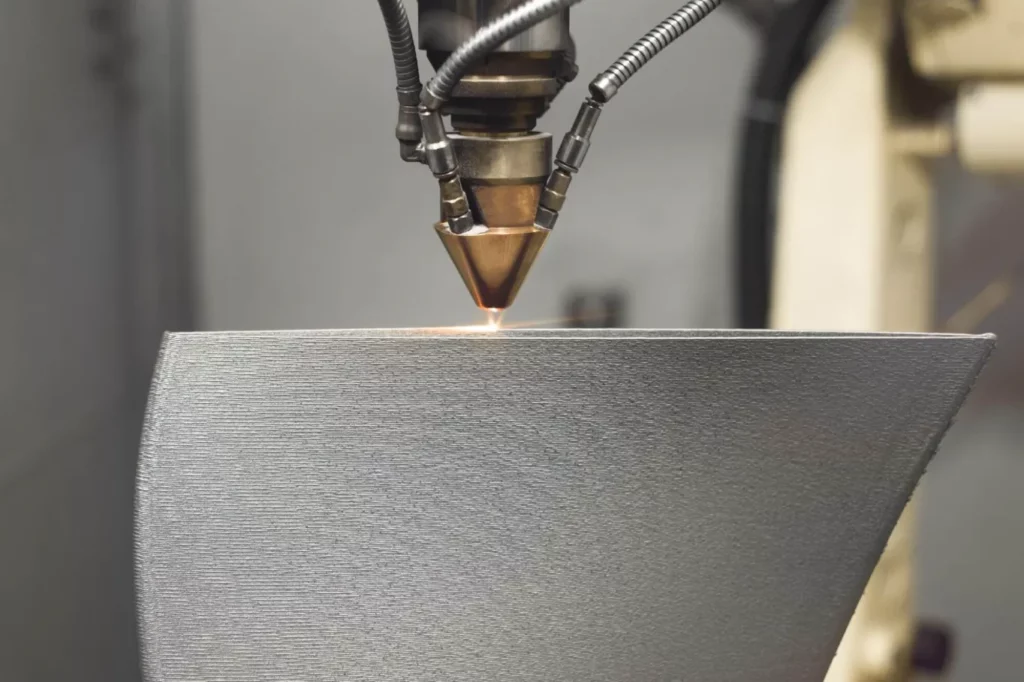

2. Strength and Efficiency with Additive Manufacturing

Additive manufacturing, widely known as 3D printing, has revolutionized the production of custom metal components. By building parts layer by layer, manufacturers can create structures that are lighter yet stronger than traditionally machined parts. This technique is particularly suited to aerospace and automotive industries where weight reduction without compromising strength is critical.

What makes additive manufacturing especially effective is its ability to minimize waste. Traditional subtractive methods often result in significant material loss. With additive processes, waste is kept to a minimum, enhancing both cost efficiency and sustainability.

3. Enhanced Properties Through Heat Treatment

Heat treatment is a vital finishing process in advanced manufacturing. It enables engineers to alter the mechanical and physical properties of metal components to meet specific application requirements. Processes like annealing, quenching, and tempering can increase a metal’s hardness, ductility, and wear resistance.

For instance, automotive parts such as gears and drive shafts undergo heat treatment to handle high stress and mechanical loads. Selecting the right heat treatment process depends on the metal’s alloy composition and intended use, ensuring precise customization for optimal performance.

For intricate or heat-sensitive components, water jet cutting offers a precise, cold-cutting solution ideal for advanced metal fabrication. This technique eliminates heat-affected zones and material distortion, making it a superior option for preserving the integrity of metals during cutting.

4. Material Innovation with Metal Alloys

The development of sophisticated metal alloys has enhanced the durability and reliability of components across industries. Alloys like titanium, nickel-based superalloys, and stainless steel offer exceptional strength-to-weight ratios, corrosion resistance, and thermal stability. Applications in energy, medical, and aerospace industries heavily rely on these materials.

A notable advancement in this area is powder metallurgy, which combines metal powders to create custom alloy compositions. This technique produces components with unique properties, catering to specific industry challenges, such as extreme chemical exposure or high-temperature environments.

5. Quality Assurance with Non-Destructive Testing (NDT)

Non-Destructive Testing (NDT) techniques are instrumental in ensuring the prolonged reliability of metal components. Using ultrasonic, radiographic, or magnetic particle testing, manufacturers can identify internal flaws without damaging the part itself.

For instance, NDT is essential in industries like oil and gas where pipe systems operate under immense pressure. By detecting defects early on, businesses avoid costly operational failures and maintain compliance with stringent safety standards.

6. Automating Supply Chains with AI and IoT

Advanced manufacturing isn’t just about production techniques; it’s also enriched by the integration of Artificial Intelligence (AI) and Internet of Things (IoT) technologies. Smart machinery equipped with IoT sensors can monitor performance in real time, predicting wear and tear before it leads to failure. AI-driven analytics further help optimize production schedules and resource allocation.

For instance, in the production of custom metal components, AI can analyze historical data to suggest process improvements that enhance consistency and reliability. This reduces material waste, shortens lead times, and maximizes operational efficiency.

7. Incorporating Green Manufacturing Practices

Sustainability is becoming a key pillar of advanced manufacturing. Techniques such as material recycling, energy-efficient machinery, and cleaner emissions offer a more eco-friendly approach to producing metal parts. Circular manufacturing methods, which involve reusing scraps and waste products, are gaining traction.

For example, the automotive industry has adopted closed-loop recycling systems to minimize its environmental footprint while maintaining the durability of components.

The combination of innovative processes, precision techniques, and advanced materials in manufacturing is pushing the boundaries of what’s possible with metal parts. By strategically integrating these technologies into production cycles, businesses can enhance durability, improve operational efficiency, and maintain a competitive edge. Durable, reliable, and expertly crafted metal parts aren’t just a benchmark of advanced manufacturing; they are essential to driving industries forward.