Industries across the globe heavily rely on precise and efficient equipment for processing industrial powders. Whether it’s in pharmaceuticals, food production, chemicals, or even construction materials, managing powders at a granular level is a critical aspect of the operation. Precision equipment ensures optimal processing, enhancing the quality and consistency of the final product.

This blog takes a closer look at why precision matters in industrial powder processing and breaks down the critical aspects of choosing the right equipment for specific needs, including particle size reduction, material handling, and processing uniformity.

Contents

- 1 Why Precision Matters in Industrial Powder Processing

- 2 Key Challenges in Powder Processing

- 3 Types of Precision Equipment for Powder Processing

- 4 Innovations Driving Precision in Powder Processing

- 5 Future of Precision Industrial Processing

- 6 Final Thoughts on Precision Equipment for Powder Processing

Why Precision Matters in Industrial Powder Processing

Powder processing, whether for pharmaceuticals or construction materials, demands a high degree of accuracy. Imprecise methods can lead to inconsistencies in particle size, which in turn affects everything from the product’s performance to its stability and quality. Additionally, precision ensures efficiency in processing, reduces material wastage, and promotes safety in the workplace due to controlled material handling.

Both large-scale manufacturers and smaller operations understand that even a small deviation in material consistency can compromise overall results, making precision equipment indispensable.

Key Challenges in Powder Processing

Working with industrial powders introduces several challenges that precision equipment is designed to address:

1. Particle Size Reduction

One essential step in powder processing is reducing the particle size of raw materials. Depending on the industry, fine powders with a uniform particle distribution are often necessary for achieving performance specifications such as solubility, uniform mixing, or even surface coverage in coatings. Particle size reduction machines play a critical role here, enabling manufacturers to break down substances into specific, consistent particles.

Whether through milling, grinding, or crushing, effective particle size reduction leads to better product quality, longer shelf life, and easier integration into manufacturing lines.

2. Material Handling

Transporting and managing powders can become a logistical hurdle in industries dealing with massive quantities of raw materials. Powders present unique challenges such as clumping, difficulty moving through machinery, or even waste during transfer. Precision material handling systems, like pneumatic conveyors or vibratory feeders, are engineered to optimize powder flow while minimizing loss and contamination. To enhance the efficiency of your industrial processing, consider integrating a lazy susan turntable, designed to streamline operations and improve workflow. This type of equipment can be especially helpful when coordinating the movement of materials between processing stations, allowing for smoother transitions and reduced manual handling.

3. Achieving Processing Uniformity

Industrial processes often involve mixing or blending powders to achieve uniform chemical or physical compositions. Precision mixers and blenders are specially designed to avoid separation or uneven distribution of mixed materials. They ensure the final product meets strict quality standards.

Types of Precision Equipment for Powder Processing

Selecting the right precision equipment is dependent on your specific industrial needs. Below are some commonly used tools in modern powder processing:

1. Crushers and Particle Size Reduction Machines

Crushers and particle size reduction machines are crucial for breaking down materials into precise, consistent particle sizes. They effectively handle a wide array of substances, from soft powders to hard granules, ensuring each batch meets stringent requirements.

2. Powder Conveying Systems

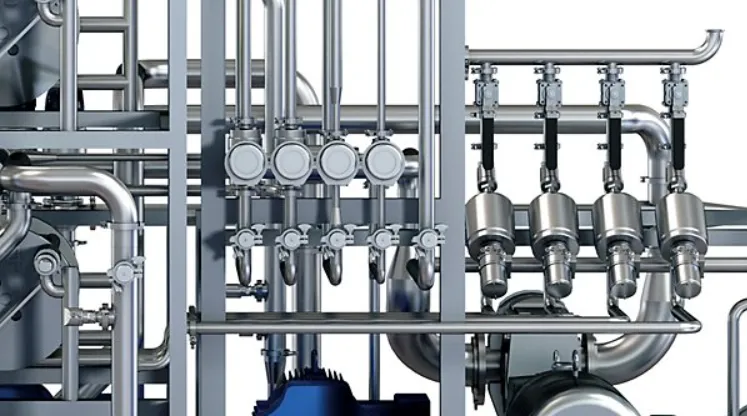

Pneumatic systems and closed conveyors ensure efficient powder transport, reducing contamination risk and material wastage. These systems are tailored to maintain the integrity of fragile or delicate powders as they transfer between processing stages.

3. Mixing and Blending Equipment

Advanced mixers and blenders maintain consistency, even with complex multicomponent materials. Whether it’s ribbon blenders, tumble mixers, or paddle-style designs, this equipment is integral to high-precision applications.

4. Screening and Classification Tools

Screening equipment removes unwanted oversized particles, while classifiers segregate materials into specific sizes. Both are vital for scaling industrial operations and maintaining output quality.

Innovations Driving Precision in Powder Processing

New advancements in automation and digital integration are revolutionizing industrial powder processing. Innovations like real-time particle size analysis, AI-controlled machinery, and smart sensors are improving efficiency by providing data-driven insights. These tools not only enhance the precision of equipment but also lead to decreased downtime and predictive maintenance capabilities.

Additionally, eco-conscious engineering designs are becoming more common as companies strive to reduce their environmental footprint. Integrated systems aimed at maximizing energy efficiency are now a key trend in newer processing equipment.

Future of Precision Industrial Processing

With industries constantly pushing for higher efficiency and cost reduction, precision technology will continue to evolve. The integration of IoT-connected systems and AI promises to deliver even greater levels of control during powder production and handling. Machines that learn, adapt, and predict will pave the way for fully autonomous workflows, ensuring smoother operations across sectors.

The demand for tailored solutions is also increasing, as industries recognize that one-size-fits-all equipment cannot address their unique needs. Customizable solutions for particle size reduction, material blending, or powder flow optimization will dominate the market in the coming years.

Final Thoughts on Precision Equipment for Powder Processing

Precision equipment has become an integral part of industrial operations with strict requirements for quality, efficiency, and safety. From reliable crushers to state-of-the-art blending systems, investing in the right tools can define the success of any industry dealing with powders.

Whether your focus is on particle size reduction, uniformity, or efficient material transport, choosing equipment engineered for precision is essential for achieving consistent, high-quality results in today’s competitive landscape.