Accreditation in the rope access industry matters because it is the clear standard for safety, technical skill, and responsibility in high-risk work. When people are working at height or in confined spaces, there is no room for mistakes. Accreditation confirms that every technician has passed tough, independent tests and that the company follows a recognised international safety system. By choosing a certified partner like RAIL – rope access company, clients are not just hiring people with climbing gear; they are investing in a planned risk-control system that protects workers, property, and reputation.

Rope access has grown from recreational climbing and caving into a highly organised industrial method largely thanks to accreditation bodies. Today, it is seen as one of the safest and most efficient ways to reach difficult areas, from glass skyscraper facades to complex offshore oil and gas structures. Without accredited oversight, the industry would lack standard training, agreed work methods, and strict safety rules, all of which have helped create its excellent safety record over recent decades.

Contents

- 1 What Does Certified Rope Access Mean?

- 2 Key Rope Access Accreditation Bodies

- 3 How Accreditation Improves Safety and Quality

- 4 Benefits of Using Accredited Rope Access Technicians

- 5 Why Clients Should Insist on Accreditation for Rope Access Work

- 6 Choosing an Accredited Rope Access Service Provider

- 7 Final Thoughts: The Impact of Accreditation on Safe and Successful Rope Access Projects

What Does Certified Rope Access Mean?

Certified rope access is a professional way of working where technicians use two ropes-a main working line and a backup safety line-to do tasks at height. But certification is about much more than the gear. It shows that technicians have passed formal exams run by independent assessors and that their employer belongs to a trade association that carries out regular, strict audits of safety systems and equipment records.

Being “certified” also means following a set Code of Practice, such as the IRATA International Code of Practice (ICOP). This document covers everything from how to choose anchor points to how to plan a rescue. It makes sure every move a technician makes while on the ropes follows a proven method designed to prevent falls. It is a complete safety approach that covers training, supervision, and the condition of all equipment.

Risks of Choosing Non-Accredited Rope Access Providers

Using a non-accredited provider brings serious legal and physical risks to a project. Without an accreditation body checking them, there is no reliable proof that technicians have the rescue skills needed in an emergency. If something goes wrong, a non-certified team might not have a workable rescue plan, which can cause long delays in getting medical help. This weakness puts workers at risk and also puts the client under strong scrutiny over their duty of care and health and safety responsibilities.

From a legal and money point of view, hiring contractors without proper checks can lead to heavy consequences. Many insurance policies for major construction or maintenance work clearly state that high-risk tasks must be done by accredited professionals. If an accident happens and the provider is not certified, insurance claims can be rejected, regulators may issue large fines, and the client’s reputation may suffer long-term damage. The apparent “savings” of using a non-accredited firm are often tiny compared to the possible cost of a single serious incident.

Key Rope Access Accreditation Bodies

IRATA Certification: Global Safety Standard

The Industrial Rope Access Trade Association (IRATA) is widely seen as the leading standard in the industry. Set up in the UK in the late 1980s to meet the tough demands of the offshore oil and gas sector, IRATA has grown into an international authority with over 600 member companies and more than 100,000 certified technicians worldwide. Its main goal is to keep rope access safe and controlled through a strong system of training and auditing.

IRATA has a truly global reach, with its rules followed in more than 160 countries. The association applies strict membership rules; companies cannot simply sign up-they must prove they are competent through an initial audit and then pass regular follow-up audits to keep their status. This means any firm using the IRATA logo is held to very high standards of performance and safety, making IRATA a trusted choice for project managers around the world.

SPRAT Certification: North American Leadership

While IRATA is highly visible worldwide, the Society of Professional Rope Access Technicians (SPRAT) is a key authority, especially in North America. SPRAT was created to meet the specific rules and industrial needs of the United States and Canada, setting out safe work practices and certification that fit local laws. Over time, SPRAT has gained strong respect and is now recognised in other regions too, including Australia.

SPRAT focuses on standards built through agreement between industry experts. Like IRATA, it offers a three-level technician certification system that stresses safety, efficiency, and professional behaviour. Its rules for moving between levels are slightly different from IRATA’s, but it keeps high demands for technical ability and rescue skills, so certified members can handle demanding industrial work.

Comparing IRATA and SPRAT for Rope Access

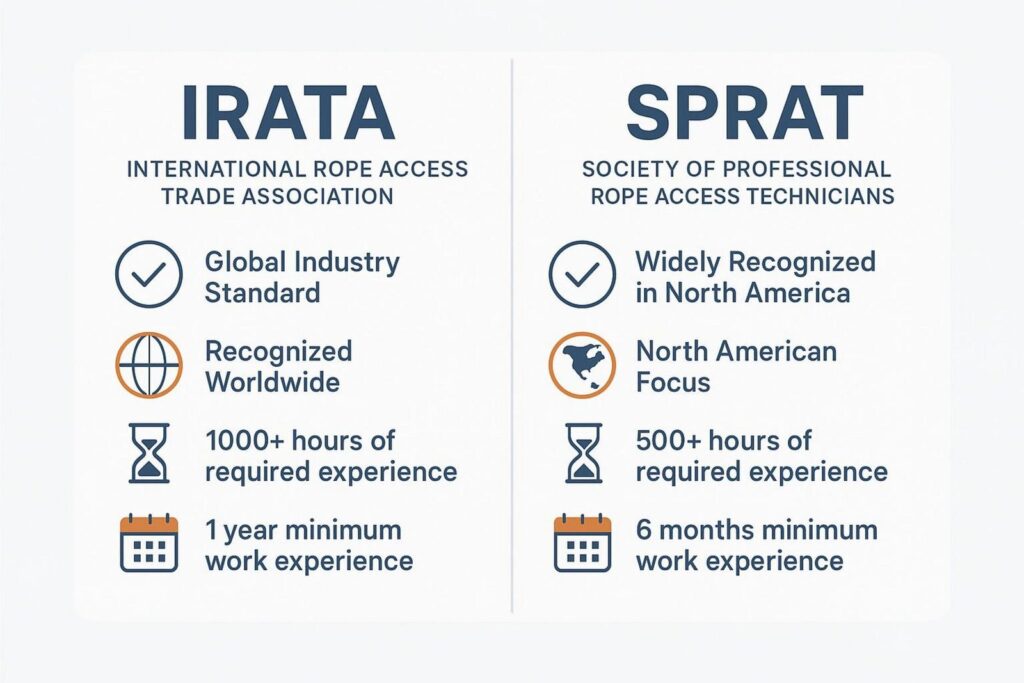

The main difference between the two systems lies in how technicians move up through the levels. IRATA usually requires a technician to log 1,000 hours of experience and at least one year of work at their current level before progressing from Level 1 to Level 2, or from Level 2 to Level 3. SPRAT often allows quicker progress, commonly requiring 500 hours and six months of experience between levels. This can make SPRAT appealing for technicians who want faster career growth, while IRATA’s longer “time on the ropes” is often viewed as producing a more experienced workforce.

Another difference is how easily the qualifications are accepted across companies. Both certifications are highly respected, but some IRATA member firms will only employ IRATA-certified technicians to match their own audit requirements. In the US, sectors such as geotechnical work and wind energy often prefer SPRAT because it fits with American safety rules. Both organisations share the same basic aim: keeping everyone safe while working on ropes, using the two-rope system as the core safety measure.

How Accreditation Improves Safety and Quality

Intensive Training and Skill Checks

Accreditation makes training a serious test, not a box-ticking exercise. Technicians go through intensive hands-on courses followed by a practical exam run by an independent assessor who is separate from the training centre. This independence is key; it confirms that skills are checked against strict, unbiased standards. Technicians learn everything from simple rope moves to advanced rigging and complicated rescue techniques, so they can handle both the physical effort and the mental pressure of the job.

Skill checks do not stop after the first certification. Because tools, equipment, and safety rules change over time, technicians must be reassessed every three years for IRATA or every two years for SPRAT. This stops skills from fading and keeps workers current with modern best practice. These regular re-tests help keep a “Level 3” supervisor today at the same high standard as someone who qualified many years ago.

Safety Procedures and On-Site Control

A key rule of accredited rope access is that a Level 3 Supervisor must be present on every job. This person is a very experienced technician trained in advanced rope work, risk assessment, site management, and emergency response. The Supervisor plans the work, manages team safety, and makes sure there is a clear, workable rescue plan before anyone leaves the ground. This level of control on site is one of the main reasons accredited rope access has such a strong safety record.

Alongside personal oversight, accreditation sets strict rules for paperwork and gear control. Every item-from the smallest karabiner to the longest rope-must have its own ID, be checked regularly, and be recorded. Accredited companies must use formal Risk Assessments and Method Statements (RAMS), which are detailed documents explaining exactly how the job will be done safely. This planned approach removes guesswork and builds safety into the project right from the start.

Ongoing Learning and Development

Industrial access work changes quickly, with new building materials, tools, and designs appearing all the time. Accreditation bodies support a culture of ongoing learning by running knowledge-sharing events and updating their Codes of Practice using new safety data. This means accredited technicians are part of an active professional community that focuses on improving techniques and adopting safer methods.

This focus on learning leads directly to better results for clients. Technicians who are retrained and tested regularly are more likely to work with accuracy, care, and good judgement. Whether they are doing a fine-detail inspection or repairing a wind turbine blade, the discipline created by a structured certification path helps them complete the job to a high standard the first time.

Benefits of Using Accredited Rope Access Technicians

Strong Safety Record and Legal Compliance

The clearest benefit of using accredited technicians is their proven safety record. Statistics show that IRATA-supervised rope access is among the safest ways to work at height and often compares well with methods like scaffolding or mobile elevating work platforms (MEWPs). For clients, this means a much lower chance of accidents, protecting workers and keeping projects running on schedule.

Using accredited services also keeps a project in line with national and international rules. In the UK, for example, accredited rope access fits neatly with the Work at Height Regulations 2005, LOLER (Lifting Operations and Lifting Equipment Regulations), and PUWER (Provision and Use of Work Equipment Regulations). By hiring a certified company, project managers can be confident they are meeting their legal duties, which helps with health and safety inspections and broader corporate compliance.

Consistent Quality and Reliable Results

Accreditation acts as a filter that keeps only the most capable and professional firms active in the market. Regular audits push member companies to keep strong internal systems. This discipline shows up in the quality of their work. Clients can expect steady, repeatable results across multiple projects because technicians follow the same high training standards and agreed procedures.

Reliable performance is another key benefit of accredited teams. Their advanced rigging skills and detailed knowledge of their equipment mean they can often solve access problems that would stop less experienced crews. This practical, solution-focused mindset, backed by solid technical ability, helps them finish even difficult projects on time and to the required quality, without cutting corners.

Speed and Cost Savings for Difficult Access Work

Rope access is naturally quicker than many traditional access methods. An accredited team can often arrive and set up within hours, while scaffolding might take days or weeks to build and remove. This quick setup cuts downtime, which is especially important in sectors like oil and gas or renewable energy, where every lost hour can be expensive. Faster work often leads to lower labour costs and less disruption on site.

Cost savings also come from the small footprint of rope access. It uses minimal equipment, no heavy machinery, and usually avoids road closures. This is a big benefit for city-centre projects or sensitive sites where large structures or machines would be disruptive or cause damage. Accredited rope access teams provide a low-impact way of working that delivers high-quality results, making it a very cost-effective option for short jobs or hard-to-reach areas.

Why Clients Should Insist on Accreditation for Rope Access Work

Reducing Liability and Keeping People Safe

For facility managers and project leaders, the main concern is keeping everyone on site safe. Insisting on accreditation is one of the most effective ways to show proper care and responsibility. By checking that a contractor has valid IRATA or SPRAT membership, the client ties their project to a proven work system that has been tested over many years. This protects both the technicians and the client from the legal and moral consequences of workplace accidents.

Accredited companies are also far more likely to hold insurance specifically set up for rope access. Insurers recognise the lower risk of accredited work and are more willing to offer strong cover. For the client, this means that if an incident does happen, there is a strong financial backup in place, which stops one event from turning into a crisis that threatens the whole project.

Better Project Results and Stronger Stakeholder Trust

Large or high-profile projects usually involve many parties-investors, regulators, local communities, and sometimes the media. These groups want to see that work is being done by recognised experts. Showing IRATA or SPRAT logos on documents, method statements, and safety plans sends a clear message of professionalism and high standards. It builds trust and can help when competing for contracts or applying for permits and approvals.

Accreditation also improves documentation across the life of the project. Accredited firms keep detailed records: daily safety briefings, equipment checks, rescue plans, and final completion reports. This paperwork is valuable later on for planning maintenance or checking the long-term condition of a structure. Clients get a clear record of what was done, how it was carried out, and who carried it out, which supports long-term responsibility and traceability.

Choosing an Accredited Rope Access Service Provider

What To Check in a Certified Provider

When looking for a rope access partner, start by confirming their membership on the official IRATA or SPRAT website. A genuine provider will share their membership number and proof of their latest audit without hesitation. But do not stop there. Review their experience in your particular field-such as geotechnical stabilisation, high-rise cleaning, or wind turbine maintenance. A company with a strong track record in your sector is more likely to understand your specific technical and safety needs.

Also look at extra certifications that may apply to your work. In many industrial environments, VCA (Safety, Health, and Environment Checklist Contractors) certification is a useful bonus because it shows a broader focus on safe working. It can also help to choose companies that use up-to-date digital tools, like workforce management or reporting platforms, which give real-time updates and clearer reporting on progress and safety.

Questions To Ask Before You Hire

Before signing any agreement, ask clear questions to test the provider’s approach to safety. For example:

- “Who will be the Level 3 Supervisor on this project, and can I see their current certificate?”

- “What is your rescue plan for this site, step by step?”

A professional firm will answer directly and explain their methods in plain language. If a provider cannot clearly describe rescue steps or confirm supervisor availability, this is a serious warning sign.

Also ask about their equipment inspection system. Request recent LOLER inspection reports or internal kit logs. A company that respects its accreditation will keep careful, up-to-date records. Finally, ask for references from clients with similar access needs. Feedback about punctuality, communication, and work quality from real projects is one of the best ways to judge whether a provider truly lives up to their accredited status.

Final Thoughts: The Impact of Accreditation on Safe and Successful Rope Access Projects

Looking ahead in construction, maintenance, and energy, accredited rope access will play an even bigger role. The global move toward renewable energy, including large offshore wind farms, creates access challenges that demand highly trained and certified technicians. These complex modern structures need precise, controlled work methods that older access approaches cannot always provide. Accreditation helps the industry expand without lowering the safety standards that have supported its success over the past forty years.

Digital tools are also becoming more common within accredited systems. Online logbooks and live safety tracking make it easier to check technician hours and keep accurate equipment records. This extra transparency strengthens trust between service providers and clients. In the end, accreditation is more than a piece of paper on a wall; it is an ongoing, active promise to work safely and well, bringing every technician home at the end of the day while achieving strong results on some of the most demanding projects in the world.