Modern laboratories are expected to meet both performance and environmental goals. In the context of materials testing, this includes reducing waste during sample preparation without compromising results accuracy or reliability. Traditional methods of preparing tensile specimens often lead to high scrap rates, repeated tests, and inconsistent outputs — all of which contribute to unnecessary material loss and energy consumption.

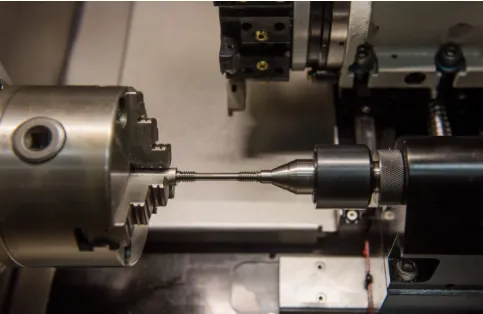

CNC tensile sample preparation offers a more controlled and efficient alternative. By automating critical steps such as cutting, shaping, and finishing, CNC systems deliver consistent results while reducing raw material use. These systems are engineered to minimize overcutting, minimize errors, and produce specimens that meet strict dimensional standards on the first attempt.

This article explains how CNC-based preparation reduces waste, promotes long-term sustainability, and helps laboratories enhance overall operational efficiency. Moreover, it outlines how modern CNC equipment contributes directly to green laboratory practices through better resource management, energy savings, and reduced environmental impact.

Contents

Waste Problems in Traditional Sample Preparation Methods

In many laboratories, tensile specimens are still prepared using manual or semi-automated machines. These methods often rely on operator skill, which introduces variability in the results. Even small errors in cutting depth, alignment, or feed speed can cause dimensional inaccuracies. As a result, specimens are frequently rejected before or after testing.

First, one of the most common issues is material waste. Manual machines often remove more material than is necessary, especially when operators make conservative cuts to avoid defects. This not only increases scrap volume but also reduces the number of specimens extracted from a given raw sample. In some cases, up to 30 percent of the original material may be lost due to overcutting or reworking.

Another problem is lack of consistency. When specimen dimensions vary between batches, test results become unreliable. Laboratories repeat tests, which consume more time, material, and energy. In regulated environments, repeated testing may also delay reporting and affect accreditation performance.

How CNC Preparation Reduces Scrap and Material Loss

CNC tensile sample preparation systems are engineered to perform cutting, shaping, and finishing with a high level of precision. Unlike manual methods, CNC machines follow programmed instructions, which removes variation between specimens and guarantees that each sample meets the required specifications.

This level of control greatly reduces material waste during preparation. Since CNC machines operate on exact tool paths, they remove only the necessary amount of material. There is no need to overcut to compensate for human error. As a result, more usable specimens can be produced from each raw material batch, and scrap volume is greatly reduced.

CNC systems also improve repeatability. When all samples are prepared to the same dimensions, the likelihood of specimen rejection due to dimensional errors drops sharply. This reduces the number of samples to be recut or retested.

Furthermore, advanced CNC machines have optimized cutting cycles that reduce the number of unnecessary passes. Fewer passes save time, but also minimize tool wear and energy consumption.

Improving Lab Efficiency Through Controlled Preparation

Laboratory efficiency depends on more than just fast processing. It requires reliable results, minimal waste, and reduced rework. CNC tensile sample preparation improves efficiency by automating key steps and removing manual handling variation.

When preparation is consistent, fewer tests need to be repeated due to specimen rejection or failure outside the gauge section. This reduces the total number of tests required to complete a project, which in turn lowers the consumption of raw materials, operator time, and energy. It also shortens turnaround times, allowing laboratories to meet deadlines reliably.

CNC systems enable controlled preparation by using fixed programs for each specimen type. Operators do not need to adjust feed rates, positioning, or cutting depth manually. Once the system is configured, it produces identical specimens with minimal supervision. This frees up skilled personnel to focus on other tasks while maintaining high output quality.

In addition, modern CNC machines record preparation parameters as well as cycle data. These records help identify performance trends and support continuous process improvement. Controlled preparation not only reduces waste, but it also helps laboratories function with greater accuracy, speed, and accountability.

Modern CNC Systems and Their Benefits for Green Labs

As already mentioned, CNC preparation systems improve accuracy, reduce material waste, and limit repeated testing. These core advantages make them a valuable part of sustainable laboratory practices. On top of that, modern CNC equipment has environmental benefits beyond precision and consistency.

One key feature is operational efficiency. Advanced CNC machines are designed with low-energy drive systems and intelligent automation. They enter standby mode when idle, optimize tool movement to reduce cycle time, and consume less power during active use. These features lower overall energy demand, which contributes directly to a greener lab environment.

In addition, modern systems often use minimal fluids or incorporate dry-cutting processes, which reduces the need for coolants and cleaning agents. This improves workplace safety and minimizes chemical waste and water consumption. Some models are also built with long-lasting components, reducing replacement frequency and material use over time.

Finally, integrated software allows full specimen preparation traceability. These digital records support environmental audits, internal verification, and sustainability standards. For laboratories working toward ISO 17025 or similar goals, modern CNC systems offer a measurable and practical path to cleaner operations.

Final Thoughts on Reducing Waste Through CNC Preparation

CNC tensile sample preparation offers laboratories a practical and measurable way to reduce waste, improve precision, and operate more sustainably. Unlike traditional methods, which often result in excess scrap, inconsistent results, and repeated testing, CNC systems generate accurate and repeatable specimens while using fewer resources.

By minimizing overcutting, reducing energy consumption, and minimizing chemical-intensive processes, modern CNC equipment helps laboratories meet both performance and environmental goals. Automated controls and traceable records further support operational accountability and green standards compliance.

CNC-based preparation is a valuable tool for laboratories wishing to reduce their environmental impact without compromising the quality of their tests. It is a step towards building an environment that is more efficient and responsible. Considering the growing expectation of sustainability, this approach offers both long-term benefits in terms of resource savings and alignment with future-focused laboratory practices.